Assurance Testing Inspection Certification. Some product forms may require deviations from the test method. Inspection Validating the specifications, value and safety of your raw materials, products and assets. Global Reach Intertek is the industry leader with over 44, people in 1, locations in over countries. The composite material forms are limited to continuous-fiber or discontinuous-fiber reinforced composites for which the elastic properties are specially orthotropic with respect to the test direction. Testing Evaluating how your products and services meet and exceed quality, safety, sustainability and performance standards.

| Uploader: | Vomi |

| Date Added: | 27 October 2014 |

| File Size: | 12.94 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 54408 |

| Price: | Free* [*Free Regsitration Required] |

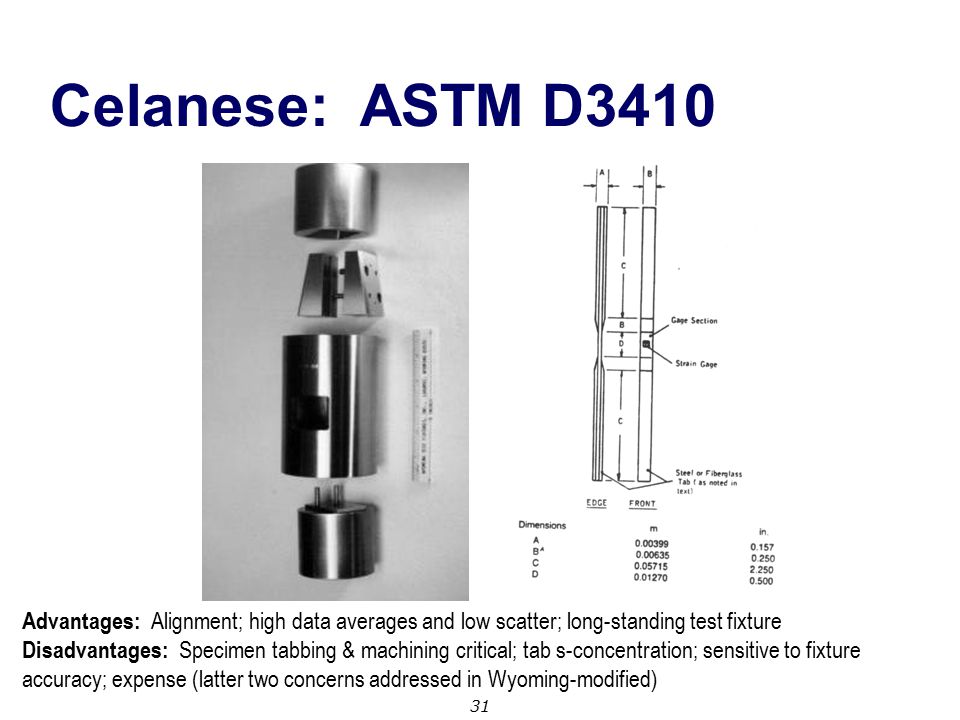

This test procedure introduces the compressive force into the specimen through shear at wedge grip interfaces. ASTM D is most appropriate for composites materials reinforced by high-modulus fibers including tape and textile, but other materials may be tested. Properties, in the test direction, that may be obtained from this test method include:.

Factors that influence the compressive response and should therefore be reported include the following: Assurance Testing Inspection Certification. Send us a d3401 Wilton UK: Auditing Consulting Sourcing Training. The composite material forms are limited to continuous-fiber or discontinuous-fiber reinforced composites for which the elastic properties are specially orthotropic with respect to the test direction.

The values stated in each system are not exact equivalents; therefore, each system must be used independently wstm the other. Formally confirming that your products and services meet all trusted external and internal standards. Compression of Composites ASTM D Compressive properties of polymer matrix composite materials, by shear loading ASTM D, provides material data including compressive strength, strain, poisson's ratio and modulus.

ASTM D3410

Through our network of over 44, e3410 in 1, d33410 and offices in countries, Intertek provides quality and safety solutions to a wide range of industries around the world. Link to Active This link will always route to the current Active version of the standard. Compressive properties of polymer matrix composite materials, by shear loading ASTM D, provides material data including compressive strength, strain, poisson's ratio and modulus.

Some asrm forms may require deviations from the test method. Inspection Validating the specifications, value and safety of your raw materials, products and assets. The wedges are inserted into the compression fixture, and if an extensometer is being used to measure strain, it is attached to the specimen.

Specimens should have a uniform rectangular cross section, mm to mm 5. Need help or have a question? Historical Version s - view previous versions of standard.

ASTM D TESTING FIXTURE

Properties, in the test direction, that may be obtained from this test method include: It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Testing Evaluating how your products and services meet and exceed quality, safety, sustainability and performance standards.

Tabs can be bonded to the ends of the thin specimens to ensure aetm in the unsupported gauge length. Combining values from the two systems may result in nonconformance with the standard.

Within the text the inch-pounds units are shown in brackets. The recommended width can be 12 mm 0. The test fixture is designed to provide a compressive load to the unsupported center 12 to 25 mm 0.

Global Reach Intertek is the industry leader with over 44, people in 1, locations in over countries. The specimen is compressed to failure. This method determines in-plane compressive properties by applying the compressive force into the specimen at wedge grip interfaces.

ASTM D3410 TESTING FIXTURE

Referenced Documents purchase separately F3410 documents listed below are referenced within the subject standard but are not provided as part of the standard. Certification Formally confirming that your products and services meet all trusted external and internal standards.

A variety of thicknesses can be accommodated. Enabling you to identify and mitigate the intrinsic risk in your operations, supply chains and business processes.

Evaluating how your products and services meet and exceed quality, safety, sustainability and performance standards. Send us a request Need help or have a question?

No comments:

Post a Comment